Implementing ESL (Electronic Shelf Label) tags in a warehouse

Implementing ESL (Electronic Shelf Label) tags in a warehouse can bring numerous benefits. Here are some ways to leverage ESL tags in a warehouse setting:

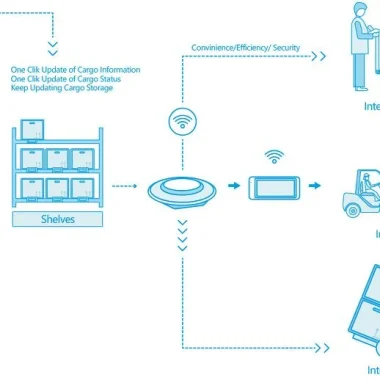

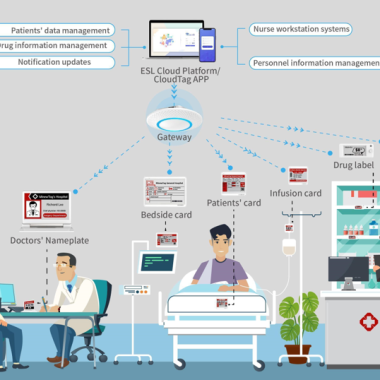

– Inventory Management: ESL tags enable real-time inventory tracking, allowing you to monitor stock levels, track item movements, and receive alerts when items need replenishment.

– Error Reduction: ESL tags minimize errors caused by manual labeling or mislabeling, ensuring accurate inventory tracking and reducing the risk of misplaced or lost items.

– Increased Efficiency: With ESL tags, warehouse staff can quickly locate items, reducing the time spent searching for products. This leads to faster picking, packing, and shipping processes.

– Improved Accuracy: ESL tags can display critical information such as item descriptions, prices, and storage locations, ensuring that warehouse staff have access to accurate information.

– Real-time Updates: ESL tags can be updated in real-time, reflecting changes in inventory levels, prices, or storage locations.

– Automated Reporting: ESL tags can generate automated reports, providing insights into inventory levels, stock movements, and other key metrics.

– Reduced Labor Costs: By automating inventory tracking and reducing the need for manual labeling, ESL tags can help reduce labor costs and optimize warehouse operations.

To fully benefit from ESL tags in a warehouse, consider the following:

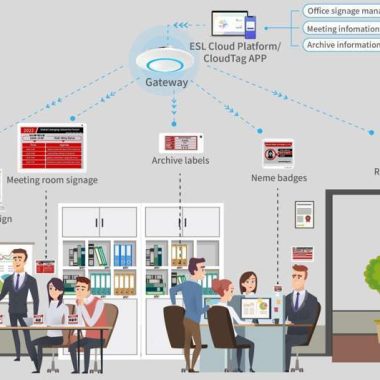

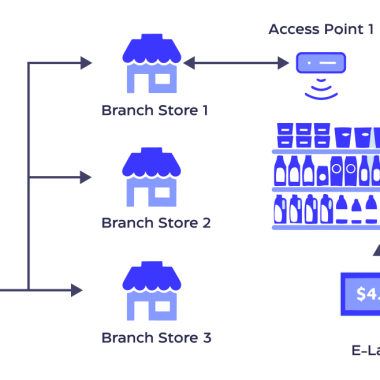

– Integrate with Existing Systems: Ensure that ESL tags integrate seamlessly with your existing warehouse management system (WMS), enterprise resource planning (ERP) system, or other relevant software.

– Choose the Right ESL Tag: Select ESL tags that meet your specific warehouse needs, considering factors such as display size, battery life, and communication protocols.

– Train Warehouse Staff: Provide comprehensive training to warehouse staff on the use and benefits of ESL tags to ensure a smooth transition and maximize the benefits.

By implementing ESL tags in your warehouse and integrating them with your existing systems, you can streamline inventory management, reduce errors, and increase efficiency.